Salt Cavern

GeoContainment™ Evaluation

For Subsurface Storage Caverns and Solution Mining Operations

1

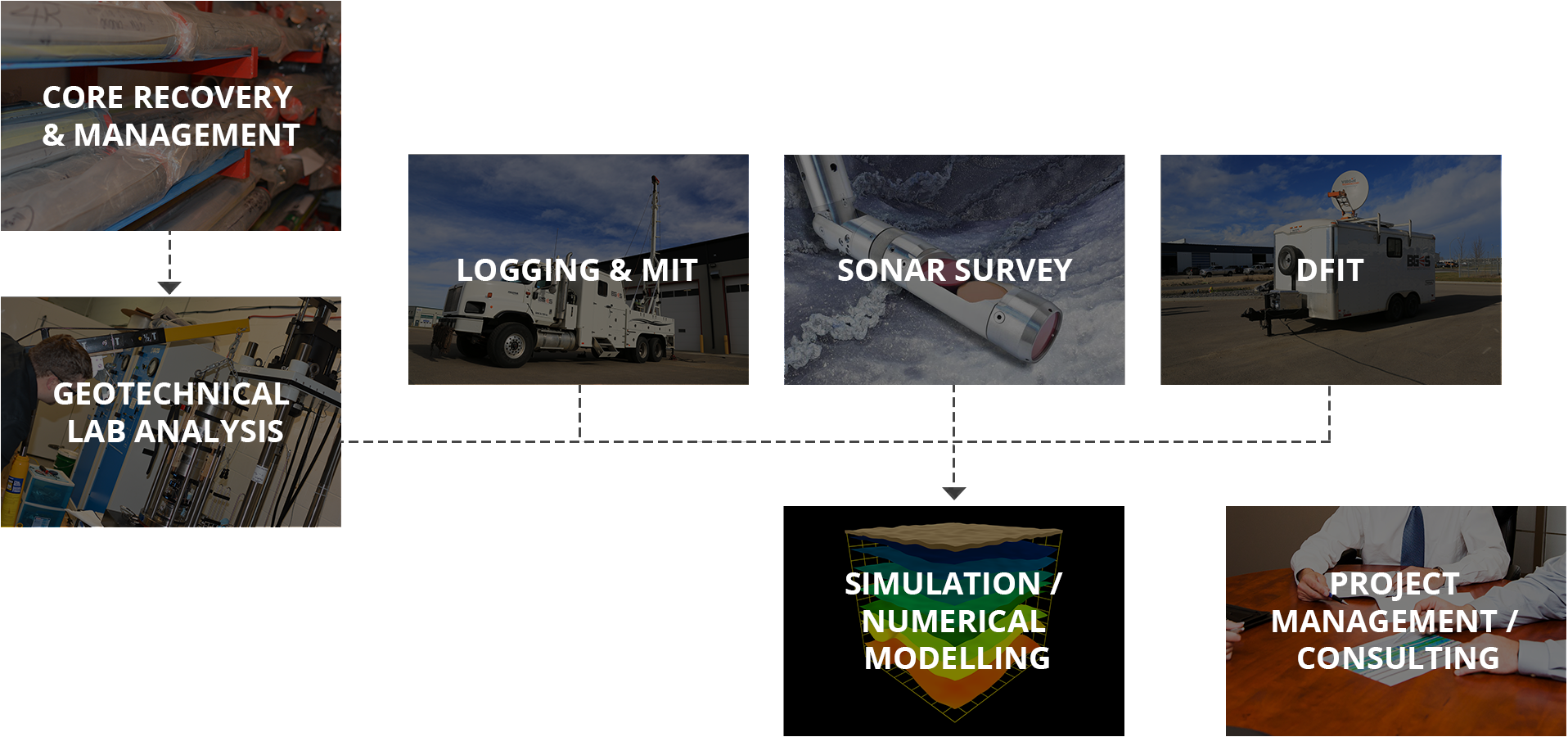

Exploration and Development1. Testing services for initial geotechnical assessment and cavern development:

- Geological & geotechnical test program design

- Salt & caprock salt cores handling and management

- Salt & caprock core laboratory analyses

- Determination of in-situ stresses using DFIT

- Numerical modelling study

- Technical reviews

2

Pre-Commissioning2. Pre-commissioning testing:

- Project planning & test program design

- Sonar survey

- Radial analysis cement bond log (RCBL)

- Casing inspection / integrity logs

- Mechanical Integrity Test (MIT)

- Technical reviews

4

Post Production / Abandonment4.Cavern abandonment and long-term integrity evaluations:

- Project planning & test program design

- Sonar survey

- Casing integrity / inspection log

- Radial analysis cement bond log

- Mechanical Integrity Test (MIT) / brine pressure test

- Abandonment

- End-of-life numerical modelling

- Technical Reviews

3

Production / Operation3. Production / operation monitoring & testing:

- Project planning & test program design

- Sonar survey

- Radial analysis cement bond log (RCBL)

- Casing inspection / integrity logs

- Mechanical Integrity Test (MIT) and pressure tests

- Multi-stage, multi-temp creep test

- Other diagnostic / monitoring logs including temperature log, noise log, and pressure-temperature-flow log

Integration of Services

Core Preservation & Management

Once the core samples arrive at our geotechnical lab, BGES ensures diligent preservation and management to maintain their integrity. We handle the cores with extreme care, immediately placing them in a controlled environment to preserve the original rock properties. This crucial step ensures that subsequent testing reflects the true characteristics of the storage formation and caprocks in-situ. After safe transport to our lab in Calgary, the cores undergo further processing and detailed analysis by our experienced technical professionals, ensuring high-quality results and reliable data.

Geotechnical Laboratory Testing

Cased-Hole Logging

Mechanical Integrity Testing (MIT)

Sonar Survey

Diagnostic Fracture Injection Test (DFIT)

BGES’ analysis approach provides consistent interpretation using a combination of diagnostic tools to give the most dependable results. A comprehensive analysis and interpretation of results is conducted by experienced technical professionals.

Project Management / Technical Reviews

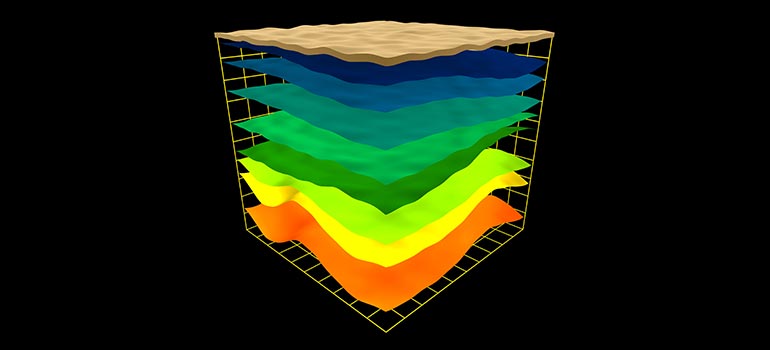

Cavern Simulation / Numerical Modelling